BP48 - Công ty TNHH MTV Tôn Hoa Sen – Bình Dương

| Tên doanh nghiệp: Công ty TNHH MTV Tôn Hoa Sen – Bình Dương | |

| Địa chỉ: Số 9 Đại lộ Thống Nhất, KCN Sóng Thần II, Phường Dĩ An, Thành phố Dĩ An, Tỉnh Bình Dương | |

| Tóm tắt dự án: Thay thế lò hơi đốt than hiệu suất thấp bằng lò hơi đốt sinh khối hiệu suất cao tại Công ty TNHH MTV Tôn Hoa Sen – Bình Dương | |

|

Hiện trạng trước khi thực hiện Các sản phẩm tôn lạnh Hoa Sen được sản xuất trên dây chuyền công nghệ NOF (Lò đốt không oxy) làm sạch bề mặt tôn tiên tiến nhất hiện nay trên thế giới, thân thiện với môi trường, tuân thủ các tiêu chuẩn: TC Mỹ: ASTM A792/A792M; TC Úc: AS 1397 và TC Châu Âu: EN 10346.

Sản phẩm của Công ty Hiện trạng và hình ảnh lò hơi cũ như sau: - Hệ thống hơi chỉ có 01 lò hơi ghi xích đốt than với công suất là 10 tấn hơi/giờ, trong khi đó công suất vận hành thực tế trung bình của lò hơi rất thấp là 2,5 tấn/giờ, bằng ¼ công suất thiết kế.

- Hiệu suất của lò cũ khá thấp, bằng 70% tính theo phương pháp trực tiếp. |

Kết quả thực hiện Tôn Hoa Sen đã quyết định hợp tác với Công ty Kim Tường Phúc để thực hiện dự án thay thế lò hơi đốt than hiệu suất thấp bằng lò hơi đốt sinh khối hiệu suất cao (công suất thiết kế 4 tấn/giờ theo nhu cầu hơi trung bình 2,5 tấn/giờ). Trong dự án này, Công ty Kim Tường Phúc sẽ là chủ đầu tư lắp đặt lò hơi đốt sinh khối mới để bán hơi cho Công ty Tôn Hoa Sen. - Hiệu suất năng lượng của lò hơi đã tăng từ 70% lên 80%. - Mức tiêu hao năng lượng để sản xuất hơi giảm từ 3,49 GJ/tấn hơi xuống còn 3,07 GJ/tấn hơi.

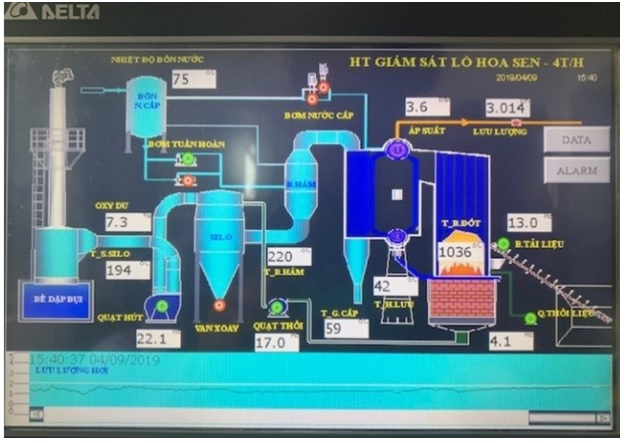

Hình ảnh màn hình điều khiển của lò hơi mới |

|

Hiện trạng trước khi thực hiện Các sản phẩm tôn lạnh Hoa Sen được sản xuất trên dây chuyền công nghệ NOF (Lò đốt không oxy) làm sạch bề mặt tôn tiên tiến nhất hiện nay trên thế giới, thân thiện với môi trường, tuân thủ các tiêu chuẩn: TC Mỹ: ASTM A792/A792M; TC Úc: AS 1397 và TC Châu Âu: EN 10346.

Sản phẩm của Công ty Hiện trạng và hình ảnh lò hơi cũ như sau: - Hệ thống hơi chỉ có 01 lò hơi ghi xích đốt than với công suất là 10 tấn hơi/giờ, trong khi đó công suất vận hành thực tế trung bình của lò hơi rất thấp là 2,5 tấn/giờ, bằng ¼ công suất thiết kế.

- Hiệu suất của lò cũ khá thấp, bằng 70% tính theo phương pháp trực tiếp. |

|

|

Kết quả thực hiện Tôn Hoa Sen đã quyết định hợp tác với Công ty Kim Tường Phúc để thực hiện dự án thay thế lò hơi đốt than hiệu suất thấp bằng lò hơi đốt sinh khối hiệu suất cao (công suất thiết kế 4 tấn/giờ theo nhu cầu hơi trung bình 2,5 tấn/giờ). Trong dự án này, Công ty Kim Tường Phúc sẽ là chủ đầu tư lắp đặt lò hơi đốt sinh khối mới để bán hơi cho Công ty Tôn Hoa Sen. - Hiệu suất năng lượng của lò hơi đã tăng từ 70% lên 80%. - Mức tiêu hao năng lượng để sản xuất hơi giảm từ 3,49 GJ/tấn hơi xuống còn 3,07 GJ/tấn hơi.

Hình ảnh màn hình điều khiển của lò hơi mới |

|

| Kết quả của dự án: | |

| Tổng chi phí đầu tư: | 4.350 triệu VNĐ |

| Năng lượng tiết kiệm: | |

| Chi phí tiết kiệm: | 1.848 triệu VNĐ/năm |

| Thời gian hoàn vốn: | 28 tháng |