BP48 - Ton Hoa Sen

| Company name: Hoa Sen Steel One Member Limited Liabilities Company | |

| Address: No. 9 Thong Nhat Boulevard, Song Than II Industrial Park, Di An Ward, Di An City, Binh Duong Province | |

| Project Summary: Replacement of a low-efficiency coal-fired boiler with a high-efficiency biomass boiler at Hoa Sen Steel Co., Ltd. - Binh Duong | |

|

Status before implementation Hoa Sen cold steel sheet products are manufactured on the NOF technology production line (oxygen-free boiler) for corrugated iron surface cleaning with the most advanced technology in the world today, which is environmental friendly and satisfactory to the following standards: USA standards: ASTM A792/A792M; Australia standards: AS 1397 and Europe standards: EN 10346.

Company products The status and pictures of the existing boiler were as follows: - The steam system had only one (01) chain grate coal-fired boiler with capacity of 10 tons of steam/hour while actual the average actual operating capacity of the boiler was very low at 2.5 tons/hour, equal to ¼ of the designed capacity.

- The efficiency of the boiler was quite low at 70% according to the direct calculation method. |

Result Hoa Sen Steel has decided to cooperate with Kim Tuong Phuc Company to implement a project to replace the current low-efficiency coal-fired boiler with a high-efficiency biomass boiler (designed capacity of 4 tons/hour according to average steam demand of 2.5 tons/hour). In this project, Kim Tuong Phuc Company acts as the investor to install a new biomass boiler for selling steam to Hoa Sen Steel Company. - The energy efficiency of the boiler has been increased from 70% to 80%. - the energy consumption for steam production was reduced from 3.49 GJ/ton of steam to 3.07 GJ/ton of steam.

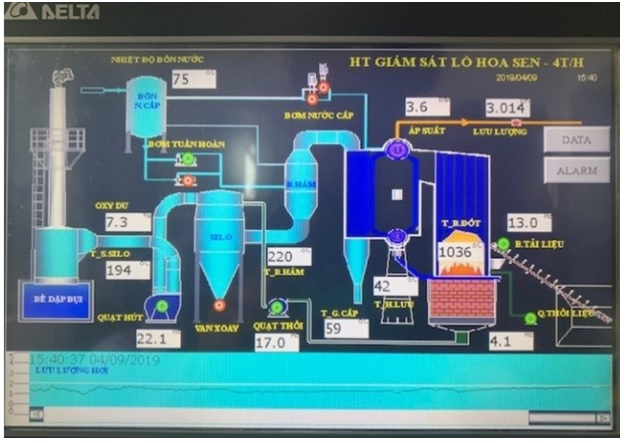

Image of the new boiler's control screen |

|

Status before implementation Hoa Sen cold steel sheet products are manufactured on the NOF technology production line (oxygen-free boiler) for corrugated iron surface cleaning with the most advanced technology in the world today, which is environmental friendly and satisfactory to the following standards: USA standards: ASTM A792/A792M; Australia standards: AS 1397 and Europe standards: EN 10346.

Company products The status and pictures of the existing boiler were as follows: - The steam system had only one (01) chain grate coal-fired boiler with capacity of 10 tons of steam/hour while actual the average actual operating capacity of the boiler was very low at 2.5 tons/hour, equal to ¼ of the designed capacity.

- The efficiency of the boiler was quite low at 70% according to the direct calculation method. |

|

|

Result Hoa Sen Steel has decided to cooperate with Kim Tuong Phuc Company to implement a project to replace the current low-efficiency coal-fired boiler with a high-efficiency biomass boiler (designed capacity of 4 tons/hour according to average steam demand of 2.5 tons/hour). In this project, Kim Tuong Phuc Company acts as the investor to install a new biomass boiler for selling steam to Hoa Sen Steel Company. - The energy efficiency of the boiler has been increased from 70% to 80%. - the energy consumption for steam production was reduced from 3.49 GJ/ton of steam to 3.07 GJ/ton of steam.

Image of the new boiler's control screen |

|

| Result of the project: | |

| Total investment costs: | VND 4,350 Million |

| Power saving: | |

| Cost savings: | VND 1,848 Million/Year |

| Payback time: | 28 months |