BP45 - Bia Hanoi Hai Duong

| Company name: Hanoi - Hai Duong Beer Joint Stock Company | |

| Address: No. 346 Nguyen Luong Bang, Binh Han Ward, Hai Duong City, Hai Duong Province | |

| Project Summary: Optimization of existing boilers’ operation and improvement of the boilers’ wall insulation for energy consumption reduction in Hanoi - Hai Duong Beer Joint Stock Company | |

|

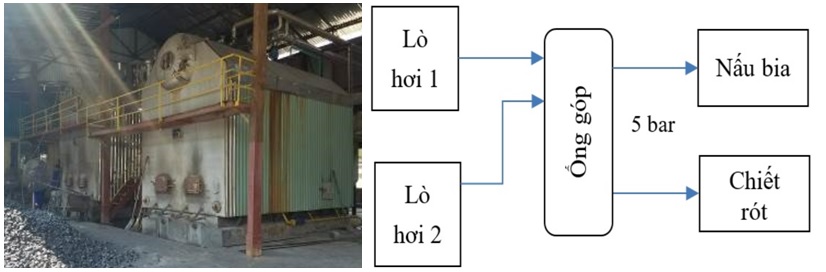

Status before implementation The steam system accounted for nearly 45.1% of the overall energy cost, including two 4B coal-fired fixed grate steam boilers with capacity of 4 tons of steam/hour/boiler. The boilers operated alternately, at a pressure of 5 bar.

Boiler and steam supply diagram The steam was used for heating process of the hops boilers (about 80% of steam output) and the filling line (about 20% of steam output). According to actual measurement and survey results, the state of the boiler was as follows: - Average oxygen content in the exhaust flue gas was at a high level of about 11%. - The feedwater was of good quality (155.7µs/cm). However, the blowdown flow was relatively high and irrational, leading to high heat loss through the boiler blowdown. The electrical conductivity of the boiler blowdown water was 1,789 µs/cm, which is too low compared to the standard of about 5,000 µs/cm. - The boiler shell insulation was not good enough, causing high heat loss through the boiler shell. |

Result The plant has implemented the following solutions: - Perform standard operating procedures developed by the consultants including blowdown process, combustion control, effective control of supplied fuel. These solutions in fact are only the changes in operation and control. They require no extra cost but bring annual coal saving of 100 tons, equivalent to a cost saving of VND 411 million/year. - Reconstruct the boiler wall to increase the heat exchange efficiency of the boiler and extend the flue gas line. This solution has helped save 59 tons of coal/year, equivalent to VND 242 million/year; Investment cost in this solution is VND 380 million, with payback time in nineteen (19) months.

Boiler wall before and after renovation To sum up, the change of operational procedure and improvement of the boiler wall have enhanced the Company’s boiler efficiency from 62.7% to 76.2%. |

|

Status before implementation The steam system accounted for nearly 45.1% of the overall energy cost, including two 4B coal-fired fixed grate steam boilers with capacity of 4 tons of steam/hour/boiler. The boilers operated alternately, at a pressure of 5 bar.

Boiler and steam supply diagram The steam was used for heating process of the hops boilers (about 80% of steam output) and the filling line (about 20% of steam output). According to actual measurement and survey results, the state of the boiler was as follows: - Average oxygen content in the exhaust flue gas was at a high level of about 11%. - The feedwater was of good quality (155.7µs/cm). However, the blowdown flow was relatively high and irrational, leading to high heat loss through the boiler blowdown. The electrical conductivity of the boiler blowdown water was 1,789 µs/cm, which is too low compared to the standard of about 5,000 µs/cm. - The boiler shell insulation was not good enough, causing high heat loss through the boiler shell. |

|

|

Result The plant has implemented the following solutions: - Perform standard operating procedures developed by the consultants including blowdown process, combustion control, effective control of supplied fuel. These solutions in fact are only the changes in operation and control. They require no extra cost but bring annual coal saving of 100 tons, equivalent to a cost saving of VND 411 million/year. - Reconstruct the boiler wall to increase the heat exchange efficiency of the boiler and extend the flue gas line. This solution has helped save 59 tons of coal/year, equivalent to VND 242 million/year; Investment cost in this solution is VND 380 million, with payback time in nineteen (19) months.

Boiler wall before and after renovation To sum up, the change of operational procedure and improvement of the boiler wall have enhanced the Company’s boiler efficiency from 62.7% to 76.2%. |

|

| Result of the project: | |

| Total investment costs: | VND 380 Million |

| Power saving: | 159 tons of coal/year |

| Cost savings: | VND 653 Million/Year |

| Payback time: | 0.6 year |