BP44 - Banh keo Trang An 2

| Company name: Trang An 2 Confectionery Joint Stock Company - Nghe An Province | |

| Address: No. 233 Sao Nam Street, Nghi Phu, Cua Lo Town, Nghe An Province | |

| Project Summary: Replacement of low-efficiency coal-fired boiler with high efficiency biomass-fired boiler | |

|

Status before implementation Trang An 2 Company was using one (01) chain grate coal-dust fired boiler with capacity of 7 tons of steam/hour and working pressure of 10 kG/cm2 and one (01) backup coal-fired boiler with a capacity of 3.5 tons of steam/hour and working pressure of 10 kG/cm2

Company’s products and pictures of chain-grate boilers Operating status of the chain grate boiler before implementation was as follows: - operating with very low efficiency (58% calculated by the direct method), requiring high fuel consumption and operating costs. - regular failure, especially the chain grate and slag remover which were usually failed due to operation under harsh environment, regularly unexpected downtime for repairing, thereby affecting the production efficiency. - Difficult to repair and replace of parts, time consuming. - Simple flue gas treatment system, the discharged dust often failed to satisfy Vietnam’s environmental standards. The oxygen concentration in the exhaust flue gas was too high (16.6% on average), indicating a very high excess of air coefficient, causing drastic heat loss through the exhaust flue gas. |

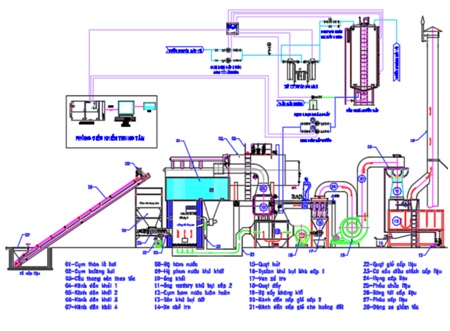

Result Trang An 2 Company then decided to replace the chain grate coal fired boiler with a fluidized bed biomass fired boiler. Overall diagram of the new boiler is as follows:

Outstanding advantages of biomass boiler technology: - Fully automatic or semi-automatic operation; boiler’s efficiency of higher than 85% - Operation cost reduced by 25 to 40% compared to that of a chain grate coal fired boiler - Thorough treatment of exhaust flue gas and dust concentration through the dry Cyclone dust filter system and wet dust suppression tower; The exhaust gas always meets Vietnamese standards - QCVN19: 2009/BTNMT |

|

Status before implementation Trang An 2 Company was using one (01) chain grate coal-dust fired boiler with capacity of 7 tons of steam/hour and working pressure of 10 kG/cm2 and one (01) backup coal-fired boiler with a capacity of 3.5 tons of steam/hour and working pressure of 10 kG/cm2

Company’s products and pictures of chain-grate boilers Operating status of the chain grate boiler before implementation was as follows: - operating with very low efficiency (58% calculated by the direct method), requiring high fuel consumption and operating costs. - regular failure, especially the chain grate and slag remover which were usually failed due to operation under harsh environment, regularly unexpected downtime for repairing, thereby affecting the production efficiency. - Difficult to repair and replace of parts, time consuming. - Simple flue gas treatment system, the discharged dust often failed to satisfy Vietnam’s environmental standards. The oxygen concentration in the exhaust flue gas was too high (16.6% on average), indicating a very high excess of air coefficient, causing drastic heat loss through the exhaust flue gas. |

|

|

Result Trang An 2 Company then decided to replace the chain grate coal fired boiler with a fluidized bed biomass fired boiler. Overall diagram of the new boiler is as follows:

Outstanding advantages of biomass boiler technology: - Fully automatic or semi-automatic operation; boiler’s efficiency of higher than 85% - Operation cost reduced by 25 to 40% compared to that of a chain grate coal fired boiler - Thorough treatment of exhaust flue gas and dust concentration through the dry Cyclone dust filter system and wet dust suppression tower; The exhaust gas always meets Vietnamese standards - QCVN19: 2009/BTNMT |

|

| Result of the project: 8,699 tons of CO2/year (100% of emission) | |

| Total investment costs: | VND 4,460 Million |

| Power saving: | |

| Cost savings: | VND 1,649 Million/Year |

| Payback time: | 2.7 years. |