BP2 - Reduce AC pressure

| Address: Yen Dinh District, Thanh Hoa Province | |

| Project Summary: A footwear company in Thanh Hoa Province has installed a loop circuit system and reset the operating pressure of the compressor. The goal of the project is to reduce energy costs and greenhouse gas emissions. | |

| Year of implementation: 2019 | |

|

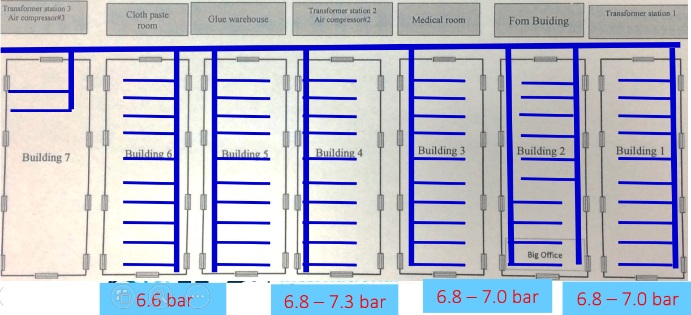

Status before implementation The installed pressure (6.5 - 8.1 bar) was higher than the demand in the factories:

Compressed air pressure at the end of the workshop (6.6 - 7.3 bar) was higher than the required level.

Diagram of existing compressed air distribution at the factory The factory’s existing compressed air distribution system is fishbone-shaped circuit system. |

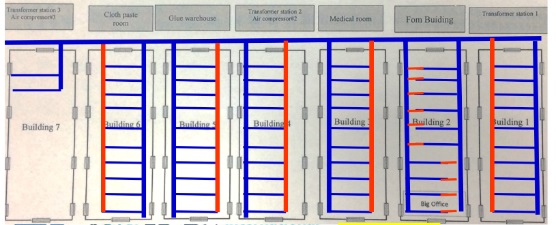

Result The factory has installed a closed loop pipeline for the distribution of compressed air on the 2nd floor of the building 12

Compressed air loop circuit diagram and image after adopting the solution The pressure loss at the door and end of the workshop is about 0.2 bar compared to 1.0 bar before Therefore, the factory can reduce the installed pressure of the compressed air system by about 0.8 bar. |

|

Status before implementation The installed pressure (6.5 - 8.1 bar) was higher than the demand in the factories:

Compressed air pressure at the end of the workshop (6.6 - 7.3 bar) was higher than the required level.

Diagram of existing compressed air distribution at the factory The factory’s existing compressed air distribution system is fishbone-shaped circuit system. |

|

|

Result The factory has installed a closed loop pipeline for the distribution of compressed air on the 2nd floor of the building 12

Compressed air loop circuit diagram and image after adopting the solution The pressure loss at the door and end of the workshop is about 0.2 bar compared to 1.0 bar before Therefore, the factory can reduce the installed pressure of the compressed air system by about 0.8 bar. |

|

| Result of the project: | |

| Total investment costs: | |

| Power saving: | 64,758 kWh/ year |

| Cost savings: | VND 119 million/ Year |

| Payback time: | |