BP32 - use servo for sewing machine

| Address: Xuyen A Industrial Park, Long An Province | |

| Name of the Manager: Mr. Phai | |

| Project Summary: A garment enterprise in Long An has replaced the sewing machines' conventional motors with servomotors, greatly reducing power consumption for the sewing machine system. | |

| Year of implementation: 2018 | |

|

Status before implementation The factory was using 488 sewing machines with conventional motors. The use of conventional motors consumed a large amount of electricity during idle times (accounting for about 70% of the total operating time).

Images of conventional motor at the factory

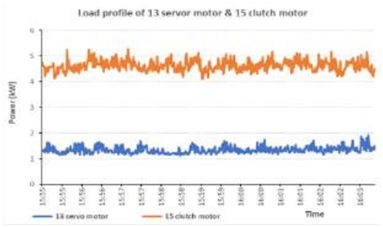

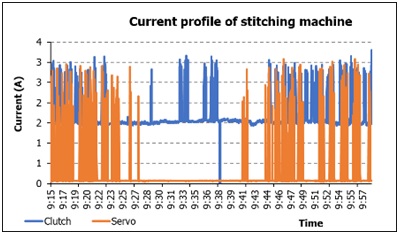

Capacity measurement results of conventional - servo motors |

Result The factory has replaced 488 conventional motors of the sewing machines with servo ones.

The servo motor installed at the factory

Capacity measurement results of installed motors Based on the measurement results, the energy saving achieved after replacing with the servomotor was about 81%. |

|

Status before implementation The factory was using 488 sewing machines with conventional motors. The use of conventional motors consumed a large amount of electricity during idle times (accounting for about 70% of the total operating time).

Images of conventional motor at the factory

Capacity measurement results of conventional - servo motors |

|

|

Result The factory has replaced 488 conventional motors of the sewing machines with servo ones.

The servo motor installed at the factory

Capacity measurement results of installed motors Based on the measurement results, the energy saving achieved after replacing with the servomotor was about 81%. |

|

| Result of the project: | |

| Total investment costs: | VND 1,915 Million |

| Power saving: | 224,870 kWh/ year. |

| Cost savings: | VND 439 Million |

| Payback time: | 4.4 years |