BP25 - HES for pressing machine

| Address: District 6, Ho Chi Minh City | |

| Project Summary: A plastic manufacturer in Ho Chi Minh City has installed HES sets for the injection molding machines to reduce power consumption. | |

| Year of implementation: 2018 | |

|

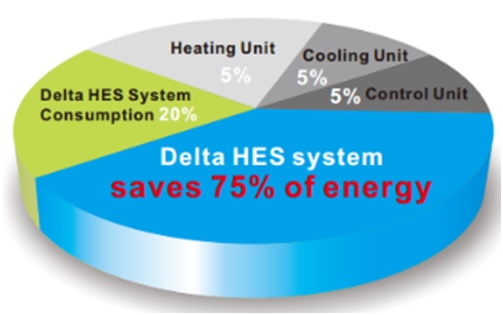

Status before implementation The power consumption of the factory's existing injection molding machines: - Hydraulic systems: 75 - 80% - Ring heater systems: 10 - 15% - Cooling systems: 5 - 10% - Control Systems: 1 - 5%

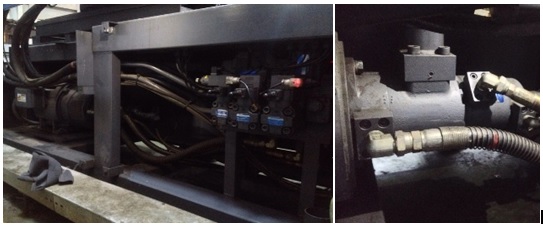

Images of injection molding machine and hydraulic pump HES sets should be considered to be installed to save up to 75% in power consumption:

Saving potential |

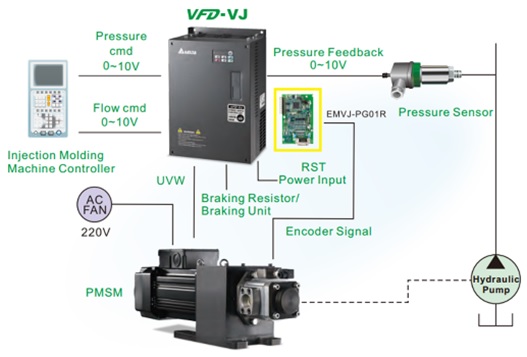

Result The factory has installed HES set for the injection molding machines, with the control principle as follows:

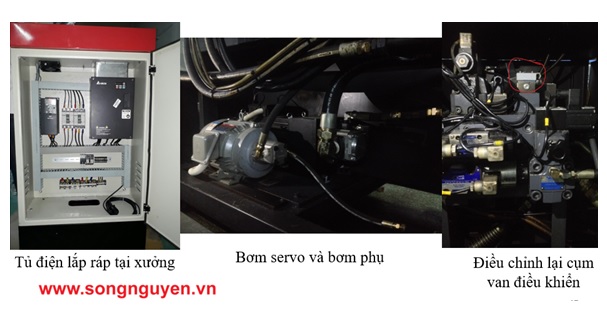

Images after installation:

After adopting the solution, the power consumption of the machine has decreased to 75 kWh/8 hours (from 285 kWh/8 hours before adoption). Oil temperature has reduced to 370 C.. |

|

Status before implementation The power consumption of the factory's existing injection molding machines: - Hydraulic systems: 75 - 80% - Ring heater systems: 10 - 15% - Cooling systems: 5 - 10% - Control Systems: 1 - 5%

Images of injection molding machine and hydraulic pump HES sets should be considered to be installed to save up to 75% in power consumption:

Saving potential |

|

|

Result The factory has installed HES set for the injection molding machines, with the control principle as follows:

Images after installation:

After adopting the solution, the power consumption of the machine has decreased to 75 kWh/8 hours (from 285 kWh/8 hours before adoption). Oil temperature has reduced to 370 C.. |

|

| Result of the project: | |

| Total investment costs: | VND 400 Million |

| Power saving: | 220,000 kWh/year |

| Cost savings: | VND 396 Million |

| Payback time: | 1 year |