BP18 - Optimize boiler blowdown

| Address: HOA XA INDUSTRIAL PARK, NAM DINH PROVINCE, VIETNAM | |

| Project Summary: A textile and dyeing enterprise in Nam Dinh province has implemented solutions to optimize the boiler’s bottom blowdown wastewater. The project objective is to reduce energy costs and greenhouse gas emission. | |

| Year of implementation: 2019 | |

|

Status before implementation Through TDS (total dissolved solids) test of the boiler water, the results are as follows:

TDS of the water inside the boiler The results show that a blowdown wastewater test is more necessary. Because this causes waste to the boiler’s water and heat. Higher blowdown means higher fuel and water consumption. |

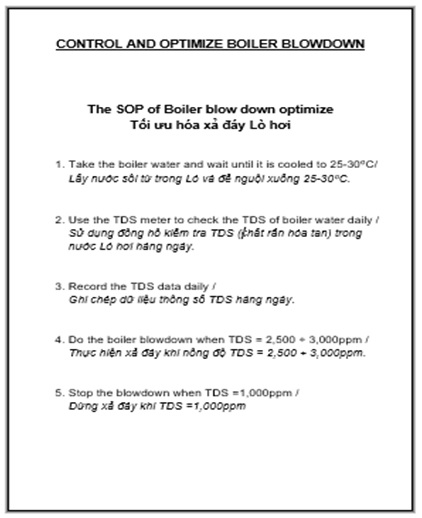

Result After optimization of the boiler blowdown, the TDS of the boiler water is under the regular control range from 2,500 to 3,000 ppm instead of 573 - 1,850 ppm according to the initial evaluation. When the TDS reaches a value between 2,500 - 3,000 ppm, the boiler operator will perform the blowdown procedure. The blowdown will stop when the TDS value reaches 1,000. Detailed SOP is as follows:

|

|

Status before implementation Through TDS (total dissolved solids) test of the boiler water, the results are as follows:

TDS of the water inside the boiler The results show that a blowdown wastewater test is more necessary. Because this causes waste to the boiler’s water and heat. Higher blowdown means higher fuel and water consumption. |

|

|

Result After optimization of the boiler blowdown, the TDS of the boiler water is under the regular control range from 2,500 to 3,000 ppm instead of 573 - 1,850 ppm according to the initial evaluation. When the TDS reaches a value between 2,500 - 3,000 ppm, the boiler operator will perform the blowdown procedure. The blowdown will stop when the TDS value reaches 1,000. Detailed SOP is as follows:

|

|

| Result of the project: | |

| Total investment costs: | VND 1.2 Million |

| Power saving: | 18.4 tons of coal/year |

| Cost savings: | VND 49 Million/Year |

| Payback time: | 0.03 year |