BP17 - Center controller and VSD for AC

| Address: HOA XA INDUSTRIAL PARK, NAM DINH PROVINCE, VIETNAM | |

| Project Summary: A textile and dyeing enterprise in Nam Dinh Province has implemented a project of installing a variable speed drive (VSD) and central control system for air compressors. The goal of the project is to reduce energy costs and greenhouse gas emissions. | |

| Year of implementation: 2019 | |

|

Status before implementation Compressor units were installed at the workshops 9 and 10. Sometimes, some compressors also simultaneously run at both load and no-load modes which cause a waste of electricity because, the compressor does not produce compressed air but consumes a lot of electricity during such off-load time.

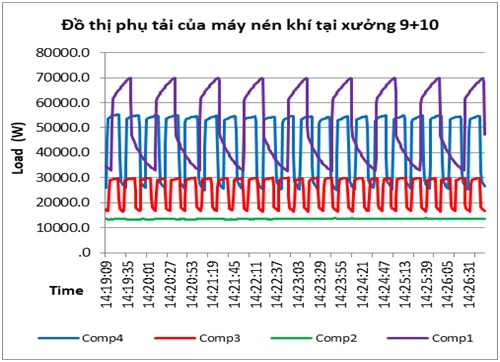

Load graph of air compressors A VSD for 01 compressor would be installed, combined with the central control system, which can help reduce the off load time of air compressors at the workshop 9 and 10. The average total capacity of the compressors was 134 kW. |

Result The factory completed the installation of the central control system and piloted VSD installation for air compressors at the workshop 9 & 10 on October 10, 2019.

Central control system & VSD After project implementation, the average power is 77 kW. Electricity saving rate equivalents to 42.5%. |

|

Status before implementation Compressor units were installed at the workshops 9 and 10. Sometimes, some compressors also simultaneously run at both load and no-load modes which cause a waste of electricity because, the compressor does not produce compressed air but consumes a lot of electricity during such off-load time.

Load graph of air compressors A VSD for 01 compressor would be installed, combined with the central control system, which can help reduce the off load time of air compressors at the workshop 9 and 10. The average total capacity of the compressors was 134 kW. |

|

|

Result The factory completed the installation of the central control system and piloted VSD installation for air compressors at the workshop 9 & 10 on October 10, 2019.

Central control system & VSD After project implementation, the average power is 77 kW. Electricity saving rate equivalents to 42.5%. |

|

| Result of the project: | |

| Total investment costs: | VND 372 million |

| Power saving: | 153,387 kWh/ year |

| Cost savings: | VND 254 million/ Year |

| Payback time: | 1.5 years |