Lighting plays the role of "repelling darkness", creating a visual comfort space for all socio-economic activities. For the industrial sector, lighting is a decisive factor to work productivity and product quality and in this field there is plenty of room for energy saving. In Vietnam, since the first export processing zone Tan Thuan was established 30 years ago, the country has 374 industrial parks with an area of 114,000 hectares and the occupancy rate of 73.3% [1]. In recent times, with the strong development of LED lighting technology, the lighting technology in general and industrial lighting in particular has moved to a period of explosive development. Internet of Things (IoT) technology is also a driving factor in the development of smart and energy-saving lighting technology.

1. Industrial lighting workspace standard

Industrial lighting must meet the following standards:

- TCVN 7114:2008 - Standard of working area lighting in terms of light intensity and quality;

- QCVN 09:2013/BXD - Regulation on economical and efficient use of energy;

- QCVN 22:2016/BYT - Standard about Lighting.

Taking into account new factors in lighting technology, from 2020 the Ministry of Construction has organized a review of the Lighting Standards and is expected to announce them in the near future.

Some of the basic criteria of these standards are summarized as follows:

- Illumination E (lux), specifying the minimum illuminance on the working surface depending on the nature and purpose of work (in the specific field of production), ensuring light in quantity.

- In terms of quality, artificial light must have colors suitable for the working place, ensuring visual comfort. Color Rendering Index (CRI) is evaluated by comparing the color of lamp light with natural light (CRI > 80 as true/accepted light).

- Ensurement of visual comfort, anti-glare ability; light does not flicker, does not cause a rotation effect that makes the eyes unrecognizable to the object being rotated.

Table 1. Summary of basic criteria of industrial lighting extracted from TCVN 7114:2008

Workspace Lighting Standards

|

No. |

Applied area |

illuminance (lux) |

CRI |

Power density W/m2 |

Glare factor limit |

|

1 |

Factory |

200 |

80 |

<13 |

19 |

|

2 |

Workspace for processing product details |

300 |

80 |

<13 |

19 |

|

3 |

Workspace of production line |

750 |

80 |

<13 |

22 |

|

4 |

Workspace for quality check |

500 |

80 |

<13 |

22 |

|

5 |

Storehouse |

100 |

80 |

<8 |

19 |

2. Economical and effective lighting technology solutions

There are many economical and efficient lighting technology solutions in general and industrial lighting in particular. In recent years, the Economical and Efficient Lighting Project funded by UNDP with implementing agencies such as the Vietnam Academy of Sciences and the Vietnam Lighting Association have organized many training courses, compiled documents [2], conducted product demonstration of LED technology. Some of the main solutions can be summarized as:

2.1. Replace gas-discharge technology lamps with compatible LEDs:

This is the most important and possible solution because the LEDs are compatible with discharge lamps so there is no need to replace the new supply system. Replacement LED luminaires manufactured by domestic companies such as Rang Dong, Dien Quang ... fully meet TCVN. They have high quality and reliability and being available in the market [3]. For industrial lighting, Rang Dong's Highbay LED luminaires have won the toprun Highest Energy Efficiency Product Award for Energy Efficiency 2020 organized by the Energy Efficiency Steering Committee of the Ministry of Industry and Trade (MOIT) and the Vietnam Energy Conservation and Energy Efficiency Association (VECEA).

Currently, many industrial enterprises, especially factories built before 2000 still use discharge lamps such as mercury lamps, sodium lamps, fluorescent lamps, compact lamps... Due to many economic/cost reasons and awareness of leaders about LED technology, old lighting systems are still used quite commonly.

The 50% power saving benefit of LED replacements - over compatible gas discharge lamps and the LED's lifespan (increased 12,000 to 30,000 hour) - will provide a quick return on investment. Note that the return on investment of replacing the old lighting system with LED technology is about 1 year if the factory works by 3 shifts.

A typical example is the Project of lighting upgrade for Hoa Binh Hydropower Plant in 2016 (implemented by Rang Dong Light Source & Vacuum Flask Joint Stock Company at the initiative of the Vietnam Electricity Association). Hoa Binh Hydropower Plant has replaced 400 sets of Russian fluorescent lights in the plant rooms with Rang Dong's LED tube lights and replaced the 250 W Sodium tunnel lights with Rang Dong's 150 W LED street lights. Based on this result, the Electricity of Vietnam (EVN) has oriented local power companies to quickly replace the old lighting system, including lighting at EVN headquarters with LED technology. The project results are shown in Table 2.

Table 2. Energy saving benefits from replacing the old lighting system

with LED lights in Hoa Binh Hydropower

|

No. |

Lighting system |

Number of bulbs |

Lamp and ballast capacity (W) |

Power consumption in 1 year (kWh) |

|

1 |

Engine room and path - 1.2m fluorescent lamp |

800 |

(40 + 10)800 = 40.000 |

8760.40 = 350.400 |

|

2 |

Engine room and path - 1.2m tube LED |

800 |

20.800 = 16.000 |

8760.16 = 140.160 |

|

3 |

Car tunnel - Sodium Lamp 250 W |

50 |

(250+50) 50 = 15.000 |

8760.15 = 131.400 |

|

4 |

Car tunnel - 150W LED floodlight |

50 |

150.50 = 7.500 |

8760.7,5 = 65.700 |

(The project's power saving efficiency is: (350,400 + 131,400) – (140,160 + 65,700) = 276,000 kWh)

The important thing when applying the solution to replace the old lighting system with LED technology is to choose products of reputable brands. Currently in Vietnam, there are more than 300 LED light suppliers, most of them only do the packing of unknown origin products, so be careful before choosing products.

When using LED lights in industry, it should be noted that some mechanical manufacturing industries (such as forging and stamping industries) use large motors, which work in short-term repeat mode with high-frequency furnaces, capacitors etc. thus generating large voltage fluctuations, causing high voltage spikes, adversely affecting the life of LEDs. So lighting cabinets must arrange additional voltage surge protection SPD (Surge Discharge Device).

2.2. Reasonable lighting design:

When starting a new lighting project, it should conduct a detailed analysis of the quality requirements of the lighting system. In addition to choose the light source of the appropriate LED luminaires, it have also needed to pay attention to the direct lighting arrangement and reasonable lamp hanging height. Since illuminance is inversely proportional to the square of the hanging height, try to place the lights at a reasonable height, which will reduce the number of installed lighting bulbs. Table 3 guides the height of the lamp according to the capacity of the lamp. It is recommended to use lighting software such as DIALUX, CALCULUX... with spatial simulation of the lighting system.

Table 3. Lamp hanging height

|

Lamp capacity (W) |

Hanging height (m) |

|

50 |

3-4 |

|

80 |

4-6 |

|

100 |

6-8 |

|

150 |

8-10 |

|

180 - 250 |

>10 |

2.3 . Thoroughly use daylight:

The design for large industrial factory needs to be calculated for using daylight with the following solutions:

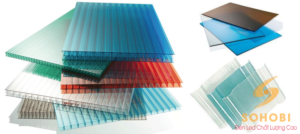

- Install places taking light from the roof with glass or clear plastic panels (Figure 1) to create a path for light to penetrate deeply into the building. This glass/plastic sheet must be durable, resistant to temperature and UV rays (figure 2).

- Use wide windows with frosted glass.

- Use light-guide system. This lighting system consists of 3 parts:

• Light-collecting dome made of transparent acrylic placed on the roof. This is a material that has the ability to block UV rays, reduce the heat transfer in the tube. The structure of the dome consists of many Fresnel telescopes, such as Solar Master's model, that allow the absorption of light with incident rays at various angles from early morning to late afternoon (figure 3).

• Conduits transmit light from the dome to the light boxes placed in the rooms. The durable anodized aluminum tube has a special inner surface coating that allows a reflectivity of 99.7%.

• The light boxes are interspersed with lights that are automatically switched on and off according to the illuminance requirements. When there is enough sunlight, the lights are off, thereby reducing power consumption.

In 2018, the Vietnam Lighting Association carried out the Project of Designing and Installing a Lighting System using a light guide system for ABB transformer manufacturing company. This system has been successfully installed at the main transformer manufacturing workshop of ABB in 81 Ngoc Hoi, Hanoi.

- Widespread use of solar panels: Industrial workshops with large roof areas are very suitable for arranging solar panels. Thanks to this renewable electricity source, it is possible to have enough electricity for self-use in factories and can be sold to the grid when generated electricity excess demand (Figure 4). Currently, the cost of the battery system, including the reserve battery and the inverter has much reduced, allowing to encourage investment in lighting systems using solar panels.

Figure1.Roof light-through spaces

Figure 2. Light-through plastic panel

Figure 3. Light-collecting dome

2.4. Automation of the lighting system for the factory:

In the 4.0 industrial revolution, sensor systems (such as optical sensors, infrared proximity sensors, ultrasonic sensors etc.) combine with microcontroller techniques and WiFi networks and artificial intelligence software for the implementation of intelligent, high-quality and energy-saving lighting systems. Figure 5 is an image of Lumi's smart switch controlled by a smartphone. This is a Vietnamese company (started-up by young engineers graduating from University of Science and Technology) that is occupying an important market share in lighting automation equipment [4].

Figure 4. Energy Solar Lighting

.jpg)

Figure 5. Lumi’s Smart Switch

3. Conclusion:

Energy saving potential for lighting in general and industrial lighting in particular is huge. The matter is to change the perception of the leadership team and technical, communication staff about this field. In terms of technology, there are many solutions that can be applied. Made-in-Vietnam products on the current market completely satisfy the demand for the field of industrial lighting./.

Assoc.Prof. Dr. Le Van Doanh

& Vietnam Energy Conservation and Energy Efficiency Association

REFERENCES

[1] Vietnam Industrial Parks, Dr. Pham Huu Thang, former Director of Investment Department, Ministry of Planning and Investment

[2] Economical and efficient lighting techniques, Science and Technology Publishing House, 2000 - Le Van Doanh, Editor-in-Chief

[3] Product catalog of Rang Dong, Dien Quang

[4] https://www.lumi.vn Lumi Smart Home