Heat Pump Overview

A heat pump is a device used to pump a heat stream at a low temperature level to a higher temperature level. The heat pumps satisfy the needs of using thermal energy at a low temperature range (40 to 95oC) such as drying, heating. , heating water... The heat pumps and the air conditioners share the same working principle under the reverse thermodynamic cycle. In order to keep a heat pump running, another flow of energy needs to be expended. They differ only in their intended use. It is called an air conditioner when using the cold source produced in the evaporator. The equipment is called a heat pump when using the hot source produced in the condenser. The most common kind of heat pump today is a 2-way air conditioner that cools the room in the summer and heats the room in the winter. The second most common heat pump today is the heat pump for hot water.

Heat pumps belong to the clean technology of the 21st century

According to Japanese experts, it is possible to save more than 50% of primary energy and reduce up to 70% of greenhouse gas emissions in the household area if heat pumps are used instead of air heaters, water heaters, etc.traditionally powered by gas, oil, and electricity.

The hot water heat pump system (Figure 1) consists of four main components: evaporator, compressor, condenser and throttle valve. Its operation is based on the specific characteristics of the intermediate substance (the medium/refrigerant) with the continuous circulation of the medium in a closed cycle, including evaporation - compression - condensation - throttling – evaporation. The heat pump can collect heat of the environment (air or water) in the evaporator to heat the water in the condenser; until the required temperature is reached, the water will be taken to the insulation tank or transmitted to the load that needs to use hot water.

Heat pump using natural refrigerant (CO2) or HFC refrigerant;

Natural refrigerant (CO2):

• Environmentally friendly and considered as a refrigerant with an ODP (Ozone Depletion Potential) of 0 and a GWP (Global Warming Potential) of 1;

• Maximum water temperature up to 95˚C is achieved in the included tanks and meets different high temperature requirements such as dishwashers;

• Many models raise the temperature from feed water temperature to high temperature with a simple operating model (some models also support circulating heating).

HFC refrigerant:

• HFC is a transient refrigerant, which will be rejected because although ODP = 0 but the GWP is quite high.

• Maximum water temperature reached 70°C;

• Operation with high reliability, relatively low cost because many parts are similar to other heat pump equipment such as air conditioner, therefore it is in easy maintenance and repair.

Application of the heat pump can save up to 75% of electricity compared to electric water heater because it collects about 3/4 of heat from the environment; it has annual operating cost much lower than using electricity, gas or oil to produce hot water.

.jpg)

Figure 1. Working principle of heat pump

Heat pump equipment can be widely applied in the field of industry, commercial buildings, restaurants, hotels, hospitals, food technology, etc. to help minimize energy consumption.

With preeminent features such as energy saving, environmental friendliness, safety for users, high durability, easy in installation, repair and maintenance, stable operation with different weather and environment, the heat pumps are recommended for use in the commercial and industrial sectors. They can compete with appliances that use electricity or gas to heat water.

Current status of heat pump use in countries

As announced by Energy Star and cited by Jonathan Trout in an article published on consumeraffairs.com, if every household in the United States uses a heat pump to heat water under 250 liters (55 gallons), the saved energy costs will amount to $8.2 billion per year. A heat pump water heater can save a family of four about $330 a year on electricity bills. That adds up to a savings of about $3,400 over the life of a typical heat pump water heater. The larger the family, the quicker the return on investment is seen.

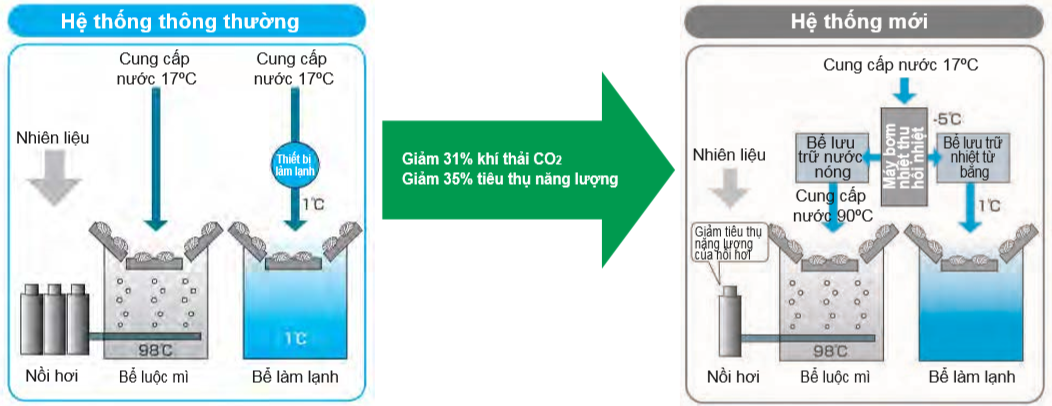

In Japan, heat pumps have been widely used in commercial buildings, especially in hospitals, hotels and even become popular with households. Tests by companies like Mayekawa, Misubishi, Daikin, Nippon... show that the heat pump has high efficiency, saves energy and has many advantages compared to conventional hot water supply equipment. This equipment is gradually replacing boilers and other traditional hot water equipment.

With efficiency higher than that of traditional boilers, heat pumps can be used to store hot water in storage tanks, shut down the system during peak hours and operate at off-peak hours with cheaper electricity, which help balance the load chart and reduce the operating cost of the power system.

There are many different types of heat pumps, from compact models for residential use to larger commercial models for swimming pools and spas. Regarding the working temperature, some heat pumps can generate 90oC hot water, even from -25oC ambient heat source. It is also possible to use a mixed hot water supply system that combines a heat pump with a traditional boiler.

A hospital in Ishikawa Prefecture, with an area of 11,665 m2 and 199 beds (figure 2), operating since 1970, installed commercial EcoCute heat pumps with a total capacity of 240 kW (30kW × 8 units) and tanks 32m3 storage space to replace oil-fired boilers with the aim of reducing operating costs. As a result of this replacement, primary energy consumption has been reduced by approximately 31%.

Figure 2. Installation of commercial EcoCute heat pumps in a hospital

Industrial heat pumps were identified as one of the key energy saving measures identified in Japan's Long-term Energy Supply and Demand Outlook, accounting for 8% of the total industry energy reduction in Japan. As mentioned above, the potential for CO2 emission reduction is greatest in the field of industrial heating.

A high temperature heat pump that can deliver hot water up to 120oC has been developed and enables a decentralized heat pump system to replace conventional centralized boiler systems. Significant energy savings are achieved not only by the energy-saving nature of the heat pump, but also by reducing the heat loss in the pipeline brought about by the distributed system.

There are two main types of industrial heat pump applications:

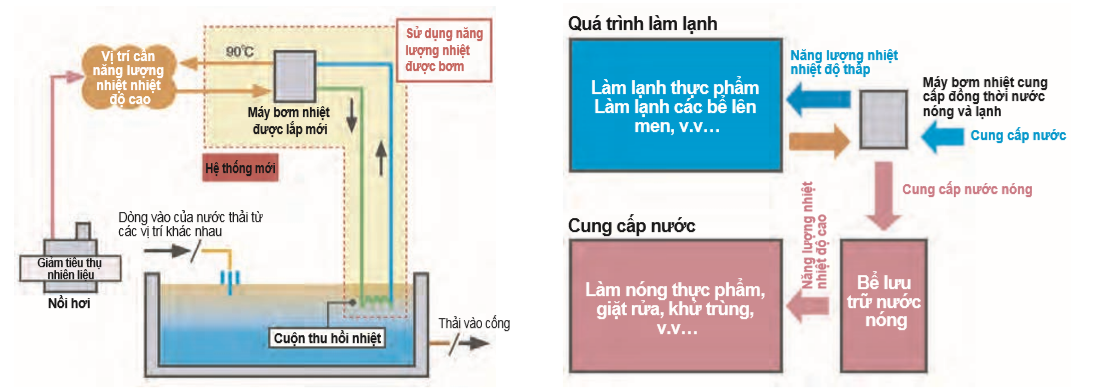

Waste heat recovery heat pump [using waste heat]:

• Waste heat that cannot be used at a temperature of several tens of degrees can be used as an effective heat source.

• In case there is a time difference between waste heat generation and heat demand, waste heat from a system of hot water tanks can be used.

Heat pump provides hot and cold water simultaneously [effective for cooling and heating]:

• Heat pump technology can be used to provide hot and cold heat simultaneously.

• In situations where both heating and cooling are required (e.g. in food processing plants), the simultaneous supply of hot and cold water results in significant energy reductions with twice the energy efficiency compared to conventional applications (using a conventional one-sided heat pump) as the energy efficiency is considered to be doubled.

Figure 3. Two main applications of industrial heat pumps (HPTCJ)

Figure 4. Simultaneous supply of hot and cold water at a noodle factory (HPTCJ)

The program "Subsidy to encourage the installation of high-efficiency heat pumps in commercial and industrial sectors" was announced by Japan on December 15, 2020, in which heat pumps with certain efficiency contributing to energy savings in factories, providing hot water and other amenities will be subsidized. This will be Japan's first subsidy for industrial heat pumps.

Heat pump market in Vietnam

Currently, there are no official statistics on the number of heat pumps used in the industrial sector, but in recent years the use of heat pumps to supply hot water has replaced devices such as: water heaters, solar water heaters in hotels, commercial buildings and households in Vietnam are becoming a new trend that brings a lot of convenience. The heat pumps are trusted and interested by many consumers.

In the market, heat pumps are being promoted and provided by many domestic and foreign companies and service providers. The number of businesses providing heat pump equipment and heat pump installation services is on an increasing trend. Those businesses are distributed mainly in Ho Chi Minh City and Hanoi.

The heat pump market in Vietnam is also very diverse in terms of types and origins, including both imported and domestically manufactured. The main brands are being introduced in the Vietnamese market such as: Jiko, Dainyo , Mitsubishi (Japan), Green Heat (USA), Accent (Australia); brands originating in Vietnam such as: SEAMAX, Megasun, Heat Pump MIMICO...

Figure 5. Some types of Heat Pumps introduced in Vietnam market

According to experts, heat pump products are quite new in the Vietnamese market, so they cause many difficulties for consumers when they need to use them. In addition to the manual from heat pump suppliers on usage techniques and maintenance policies and prices of installed heat pumps for consumers, there is no management measure of quality controlling agency to this kind of particular product.

Vietnam has a tropical monsoon climate and the North has cold winters, so the demand for heating and hot water in daily life and in industry is huge. Heat pumps with the above-mentioned preeminent characteristics should be encouraged to use. The State management agencies which in charge of product quality should take responsibility to evaluate and analyze the effectiveness of heat pump equipment. It is basis for the development of policies to encourage using heat pump equipment as well as to promulgation of detailed technical standards on the use of heat pumps in construction and industrial works./.

MBA. Mai Van Huyen

& Vietnam Energy Conservation and Energy Efficiency Association

References:

- Japan Heat Pump & Storage Technology Center (HPTCJ);

- Documents of Vietnam-Japan Business Forum on Energy Efficiency and Renewable Energy (March 17, 2021 in Hanoi).